Many shoppers, supermarkets and takeaways have ditched single use polystyrene packaging for fish suppers and salmon steaks, but much of our fish is still transported in polystyrene, one of the most pervasive pollutants on our beaches. An estimated 22 million polystyrene (EPS) fish boxes are used in the UK each year, intended for single use and then disposal[1]. In this extended Year of Coasts and Waters 2020/21, Fidra believes there’s no excuse for EPS use.

Polystyrene fish box waste © Fidra

To support our call to pass on this problematic packaging[2] we worked with environmental consultants TAUW[3] to compare alternatives to polystyrene fish boxes, and set users on a road to better boxes. The full report ‘Assessment of alternatives for EPS fish boxes‘ is available to download here.

Complicated supply chains

Supply chains in the fish industry are among the most international and complex within the food industry. The role of single-use packaging is significant and EPS is the most commonly used. Polystyrene is one of the top 10 most commonly found items in marine litter[4]. Although recovery rates for it are slowly increasing, they are still at a relatively low level overall. With alternative materials being developed, there are increasing opportunities to move away from EPS altogether.

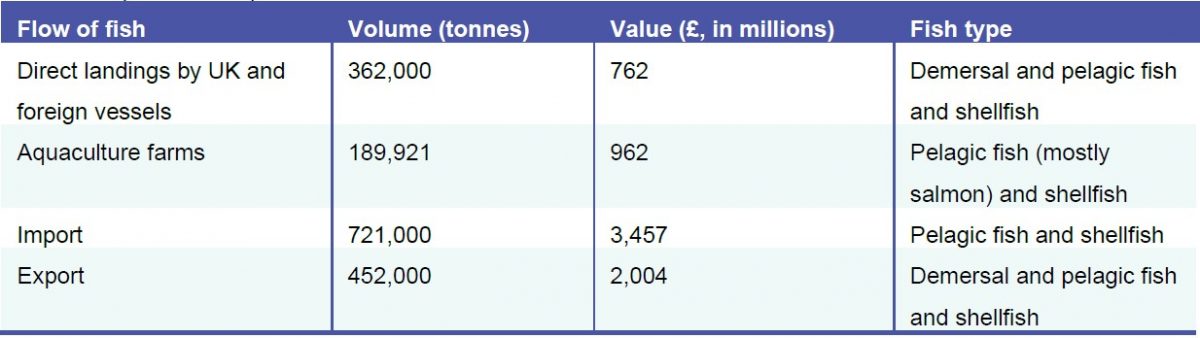

Much of the catch landed in the UK is exported, while a lot of fish is imported for UK consumption and processing (Table 1). Once fish is brought ashore there are multiple routes possible depending on fish species, the degree to which the fish has already been processed and the intended sales channel.

Table 1: Inputs and outputs of fish in the UK in 2019 [5]

Transport depends on the country of origin and whether fish is chilled or frozen. Within the UK the supply chain is well organized and a cold chain can be maintained. For wider distribution and transport, the insulating effect of fish packaging is of greater importance. Fish may be whole or filleted, chilled or frozen, and transported by air freight, container ship or lorry. Containers may be uninsulated, insulated, or temperature-controlled. Container supply chains have less handover points and handling, while air freight supply chains may have storage stages that are not chilled.

Growing innovation

Today’s growing awareness of the impact of plastics on the environment has led to innovation in the use and development of alternative materials for fish boxes, from corrugated card to more durable (and therefore reusable) plastic. To assess the suitability of alternatives requires consideration of its properties, and the conditions under which it will be used.

The report groups similar types of material together according to corresponding characteristics, and compares the different environmental effects and circularity of each group. It also considers how easy it will be to scale up alternatives. The variation and complexity of the UK seafood supply chains means that not all alternatives are suited to every part of them. To assess the relative impact on the environment, a compact indicative LCA (Life Cycle Analysis) study was applied for the complete life cycle of the identified categories of alternative solutions.

Comparing fish packaging alternatives

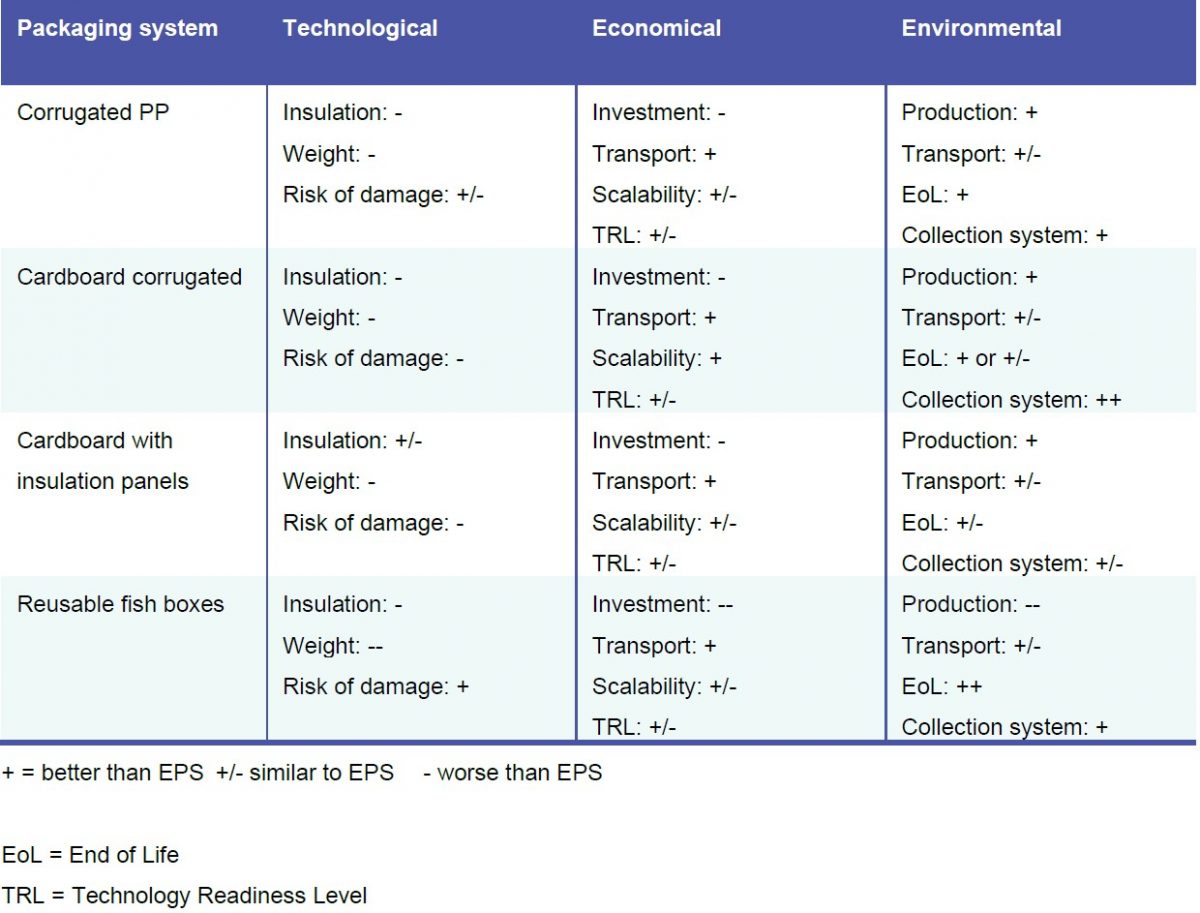

Packaging for fish can broadly be divided into five different material categories: (1) Single use plastic EPS, (2) single use plastic other (corrugated polypropylene), (3) single use corrugated cardboard, (4) single use corrugated cardboard with liner (insulation panels) and (5) reusable solid plastic packaging.

In general the alternatives score better in terms of overall CO2 footprint and environmental costs, especially for reusable solutions (Table 2). Production makes the largest contribution, while end-of-life processing methods make a relatively minor contribution. Many solutions focus on using potentially recyclable materials. However, the degree of success depends on the presence of a suitable (existing) collection structure for the waste that is released. In practice, there is often no suitable industrial route available for biodegradable or compostable materials.

Table 2: Overview of fish packaging alternatives, compared to standard EPS packaging.

Calling time on EPS

Companies are increasingly looking at alternatives to EPS for transport and storage in their supply chains. Important drivers are the desire to reduce plastic in packaging and to increase the use of fully recyclable materials. Influential parties such as supermarkets are increasingly forcing their suppliers to switch to alternatives, and smaller players also seem to be embracing alternatives.

However, the scale at which this occurs is still far too limited. Barriers that have emerged are technical packaging properties that cannot (yet) be matched, added complexity, and the investment needed to adapt existing production lines to new packaging.

Possibly the most significant barrier however is the higher cost of the identified packaging alternatives. Many indicate that they only see a larger scale breakthrough of alternatives happening, when this ‘unprofitable peak’ is eliminated by the introduction of a plastic tax on EPS transport packaging, or ultimately a ban on EPS. The UK Plastic Packaging Tax due to come into effect in April 2022 provides exemption for packaging that is used to transport goods into or out of the UK, indicating that polystyrene fish boxes would not be taxed [6]. This is a badly missed opportunity to drive positive changes in transport packaging

Currently, there is still an absolute need for companies to target alternatives to polystyrene. This means that real changes will only occur if more powerful parties such as supermarkets or wholesalers take the lead. A well-organized supply chain such as that for Scottish salmon aquaculture is in a good position to make a contribution in the right direction and accelerate a transition towards less EPS based packaging, especially for inland deliveries.

Salmon in a polystyrene fish box © Fidra

[1] http://www.eps.co.uk/adayinthelifeofafishbox/index.html

[4]https://publications.jrc.ec.europa.eu/repository/bitstream/JRC108181/technical_report_top_marine_litter_items_eur_29249_en_pdf.pdf

[5] H.M. Revenue and Customs

[6] https://www.gov.uk/government/publications/introduction-of-a-new-plastic-packaging-tax

Tags: aquaculture, EPS, farmed Scottish salmon, marine litter, plastic packaging, plastic packaging tax, polystyrene